Membrane filtration systems

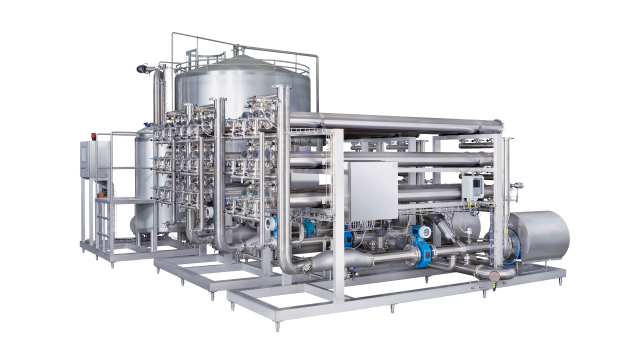

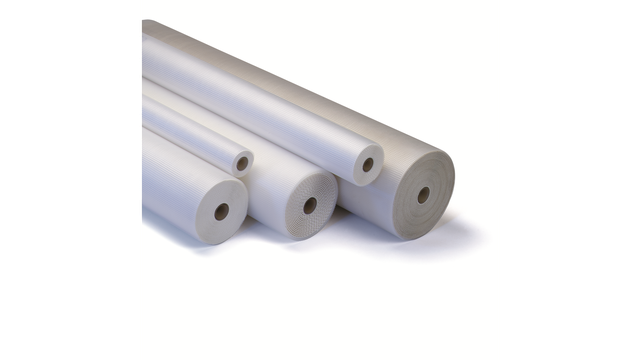

Alfa Laval designs, manufactures and installs complete cross-flow membrane filtration systems, based on polymeric membranes. Our production units are based on either the unique plate-and-frame modules or on spiral elements of varying sizes. For some applications, a combination of both types can be used to give the best possible membrane filtration solution.

Experience complete, end-to-end membrane filtration technology

- High-performance Alfa Laval membranes and filtration equipment, including modules, pilot units and fully engineered systems

- Plate-and-frame and spiral elements, used individually or in combination, for optimal high end product quality

- Customized membrane system solutions tailored to your specific process, engineered for both sanitary and industrial environments

- Seamless integration with other separation technologies

- Regulatory compliance with major global standards (EU 1935/2004, 10/2011, 2023/2006, FDA CFR Title 21) for safe and reliable processing

Engineering membrane systems for a rapidly growing world

Alfa Laval offers a complete range of cross‑flow membrane filtration solutions, manufactured in‑house. Our experience in microfiltration, ultrafiltration, nanofiltration and reverse osmosis dates back to the mid‑1960s, soon after membrane filtration was introduced on a commercial scale.

As a market leader in reliable separation technologies for sanitary and industrial applications, we offer an extensive portfolio of membrane filtration equipment, including high‑performance polymeric membranes, modules and components, laboratory test units, pilot plants, and fully engineered production systems, available for both batch and continuous operation.

Our membrane solutions, when used in industrial-scale applications where reliability, consistency and operating costs are crucial considerations, offer significant advantages.

Customized membrane filtration solutions for maximum recovery and cost‑efficient operation

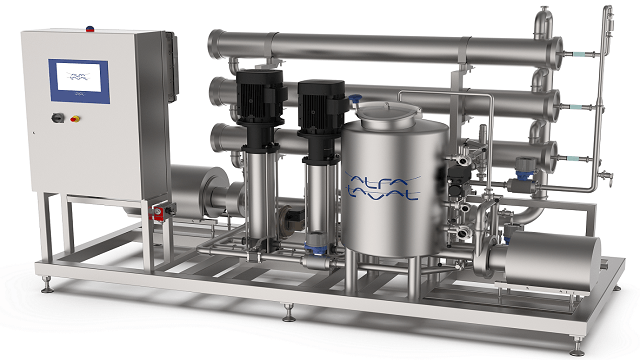

Whether your process requires a sanitary or industrial design, our experts engineer customer‑specific plants based on the unique plate-and-frame modules, the cost effective spiral elements, or a combination of both. We develop our membrane filtration systems in close cooperation with customers to secure high product purity, maximum recovery and operating efficiency. To ensure a smooth handover, we also provide validation, installation and commissioning support. Discover our range of Alfa Laval membranes and systems below:

How do Alfa Laval membrane filtration systems work?

We take pride in providing our customers with complete, optimized membrane systems that consider every aspect of the process. Each solution is designed around your specific requirements, including feed composition, operating parameters, product specifications and key cost factors, such as uptime and operating expenses. The result is stable, efficient operation and long-term value for your process.

Before making any final decisions, you can test Alfa Laval filtration technology with your own feedstock at our Membrane and Application Development Test Centre in Nakskov, gaining confidence through data‑backed results. Alfa Laval in Nakskov also serves as the group’s global headquarters for the development and manufacture of advanced membrane filtration solutions.

From lab to full scale: Discover Alfa Laval’s membrane system case stories

Read how real customer plants maintain on-spec processes across the food, beverage, dairy, biotech and pharmaceutical industries.

Submit a form and tell us your unique requirements

At Alfa Laval, we don’t deliver standard systems. Engineers, software developers, designers, metalworkers and electricians work as one team to meet your exact process needs.