Separators for food and beverage industries

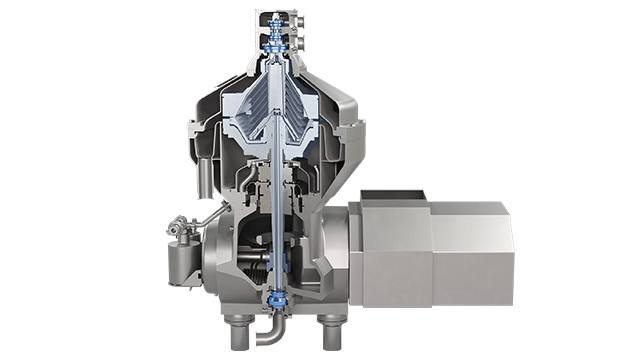

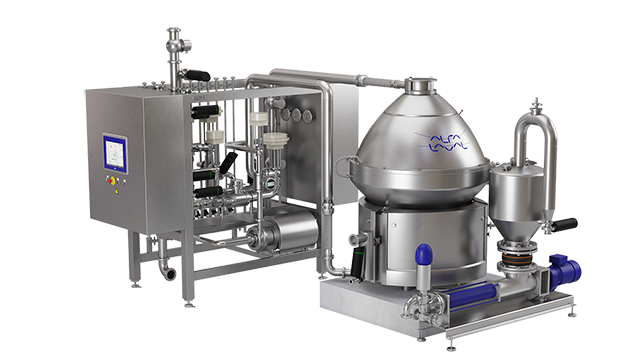

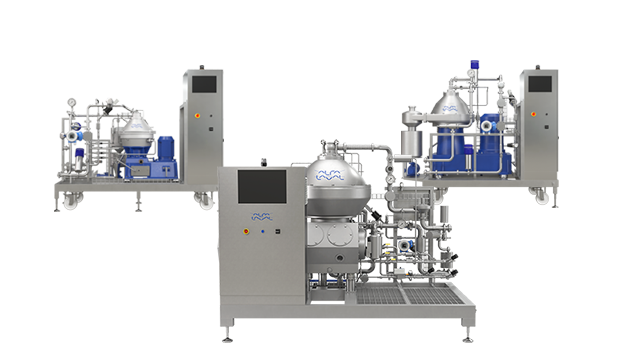

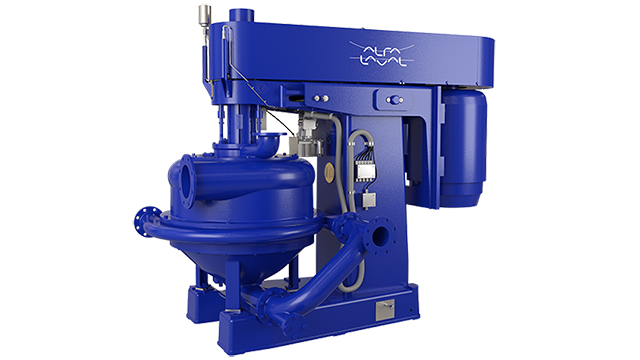

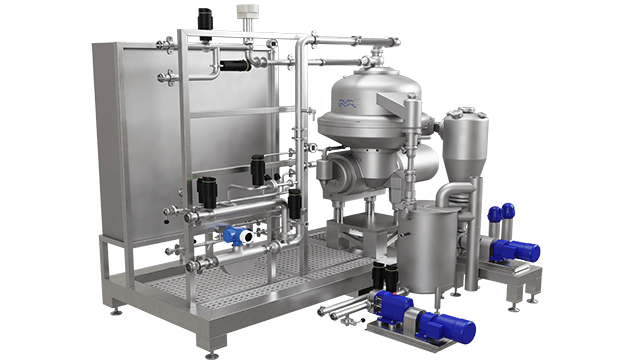

Nearly all types of food and beverage processors depend on advanced separation equipment. Alfa Laval offers a complete range of centrifugal separators for food and beverage applications, designed to meet diverse industry demands. From beverage and dairy industrial centrifuges to solutions for starch, edible oil, protein, and more, each separator model is carefully engineered to provide an optimal fit for its specific application. Enhanced product quality, hygiene, and efficiency ensure you can meet consumer and market demands today and in the future.

Experience the advantages of innovative separation technology for high quality food and beverage products

-

Safe and efficient performance for liquid-liquid and solid-liquid separation

-

Gentle handling to deliver high-quality products to your consumers

-

Features to minimize and eliminate the risk of dissolved oxygen pick-up

-

Reduced OPEX thanks to minimal maintenance needs and the market’s lowest energy consumption

-

Fast access to service support from a global network of experienced separator technicians

Your choice - our mission

Separation equipment plays a critical impact on both the quality of your products and your profitability. We have developed centrifuge technology with a focus on ensuring reliable performance along with the lowest possible total cost of ownership.

We work closely with you to identify the ideal solution from the market’s most comprehensive range of separators for food and beverage. With decades of expertise in these applications, we configure equipment to match your processes and help you achieve the unique taste and quality your products deserve.

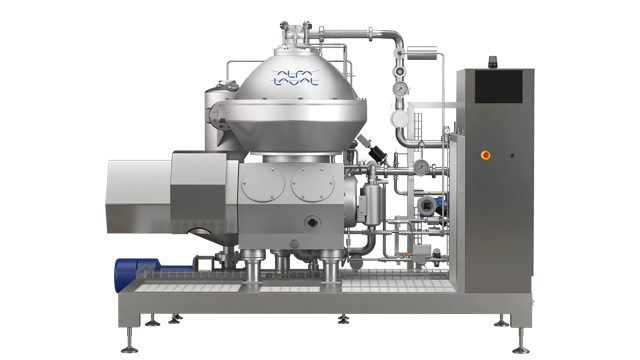

Separators for beer processing

Separators for beverage processing

Separators for starch processing

Separators for protein processing

Separators for edible oil processing

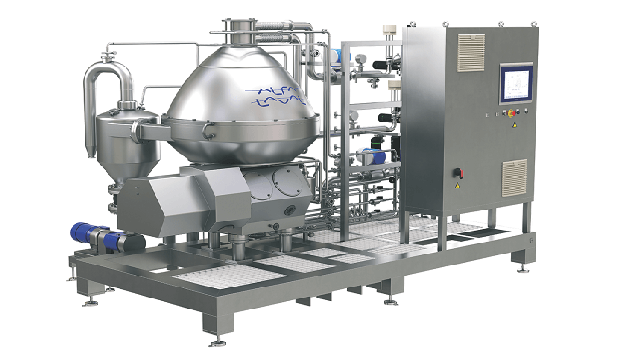

Proactive condition monitoring for maximum uptime

To ensure the best, long-term separation, breweries with top-of-the-line Alfa Laval hermetic centrifuges can also take advantage of top-of-the-line connected services. Available as part of an Alfa Laval Performance Agreement, proactive condition monitoring measures vital data about the real-time performance of your equipment and alerts you if action is needed. This helps you keep your equipment in top condition at all times and avoid the risk of costly unplanned downtime.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.