2019-06-05 Новини про обладнання

New PureSOx water cleaning system provides future-proof and cost-saving flexibility for scrubbing in closed loop

Alfa Laval PureSOx gives customers the option of scrubbing in closed loop, either by choosing a fully equipped hybrid system or by installing a hybrid-ready system that can be upgraded for closed-loop operation later. With the launch of a modular new PureSOx water cleaning system (WCS), these possibilities become even more attractive.

Though few in number and limited in scope, local bans on open-loop scrubbing have intensified the interest in hybrid scrubber solutions with closed-loop functionality. While marine customers are focused on complying with today’s needs at minimal cost, there is peace of mind in the ability to upgrade if regulations should become more stringent. Both considerations are integral to the new PureSOx water cleaning system (WCS).

“The new PureSOx WCS is a modular, customer-adapted solution that makes closed-loop operation with PureSOx even more cost-efficient,” says Erik Haveman, Sales Director, Exhaust Gas Cleaning. “Simply put, it offers vessels a future-proof system with options to expand capacity and save on operating costs.”

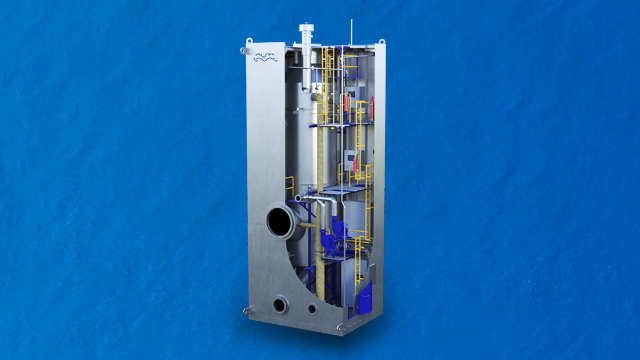

Modular options increase water-cleaning capacity

As before, the foundation of the PureSOx WCS is high-speed centrifugal separation. This is a core technology in which Alfa Laval has well over a century of experience, as well as the most effective method of cleaning water at sea. In the new modular system, the separator module can be combined with a flocculator or a membrane module for additional capacity, either directly or through a later upgrade.

“The modular additions allow the best and most cost-effective fit for the customer’s needs, building on the proven effectiveness of the centrifugal separator,” says Haveman. “Vessels with high engine power, such as mega-container vessels and cruise ships, will benefit especially from the addition of membranes, which increase the volume of water that can be cleaned effectively.”

New features lower closed-loop operating costs and increase safety

Still more benefits are achieved through two features that are new to the PureSOx WCS. One is the ability to use either NaOH or non-hazardous Mg(OH)2 as the alkaline additive, based on which is desired or most affordable at the time. The other is the option of using seawater rather than fresh water for replenishing the water system, which yields lower energy costs.

“Unless it’s bunkered, fresh water has to be produced on board, which means using it for closed-loop scrubbing adds to the energy equation,” says Haveman. “Seawater replenishment makes economical use of water that’s readily available to the vessel.”

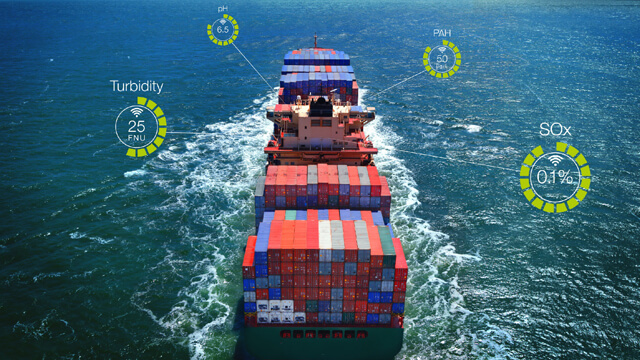

A flexible hybrid offering – proven in 10 years at sea

With the new capabilities of the PureSOx WCS, Alfa Laval adds strength to an already convincing hybrid system offering. Hybrid PureSOx systems have excelled in a decade at sea, ever since the very first PureSOx system – also a hybrid – set sail on DFDS Ficaria Seaways in 2009.

For customers who hesitate to commit to a hybrid today, but who still wish to future-proof their scrubber investment, Alfa Laval provides PureSOx systems as hybrid-ready. This option, which is Alfa Laval’s standard for open-loop deliveries, includes the connections, hardware accommodations and software flexibility needed for a later hybrid upgrade. The upgrade can be done at a shipyard quay, or in some cases while the vessel is sailing.

“PureSOx customers can be confident of complying with stricter regulations if they appear,” says Haveman. “Whether they choose a fully equipped hybrid system now or opt for a hybrid-ready system that can be upgraded later, they can count on the most effective water cleaning technology available. Alfa Laval has ten years of closed-loop operating experience to prove it.”

To learn more about Alfa Laval PureSOx and Alfa Laval’s approach to exhaust gas cleaning, visit www.alfalaval.com/puresox

Editor’s notes

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, in oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena. Alfa Laval is listed on Nasdaq OMX, and, in 2018, posted annual sales of about SEK 40.7 billion (approx. 4.0 billion Euros). The company has about 17 200 employees.