2019-05-15 Новини про обладнання

New Shanghai training facility prepares engineers for Alfa Laval PureSOx commissioning

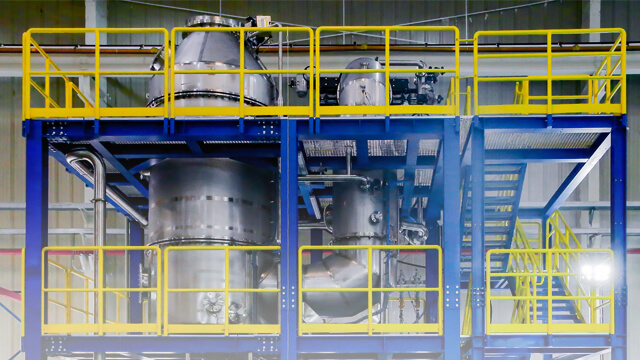

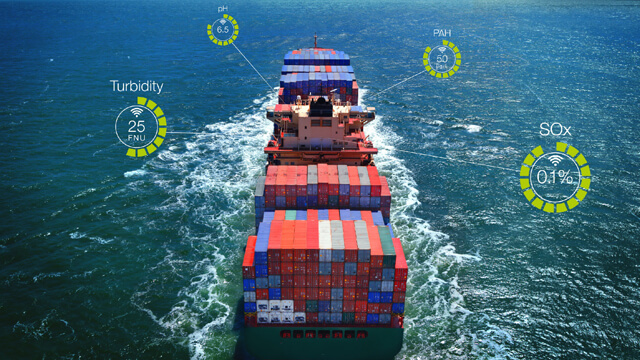

Recently, Alfa Laval inaugurated the Alfa Laval PureSOx Training Centre in Shanghai, China. Focused on the training of commissioning engineers, the new facility will be instrumental in ramping up the skilled workforce prior to the global sulphur cap. But with its full-sized PureSOx scrubber, it will also provide crew training opportunities for customers.

Alfa Laval has not only invested heavily in PureSOx manufacturing operations, but is also working to further expand its service and training resources in exhaust gas cleaning. As more PureSOx scrubbers are installed to meet the global sulphur cap, skilled local engineers will be required to commission the many systems.

“As the need grows, both the availability and the quality of local knowledge will be essential in meeting it,” says Erik Haveman, Sales Director, Exhaust Gas Cleaning. “The Alfa Laval PureSOx Training Centre in Shanghai will support both our global efforts and the preparation of commissioning engineers in Northeast Asia.”

Accurately recreating the onboard experience

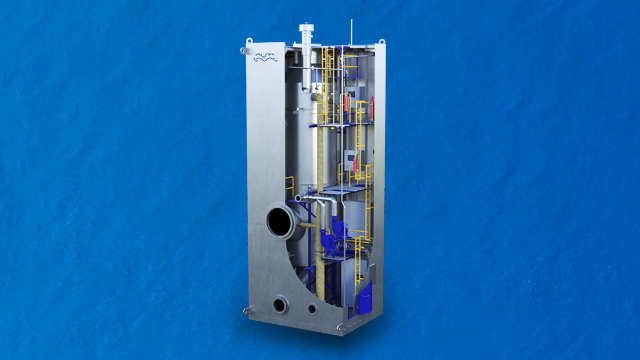

With its full-sized PureSOx scrubber system, the new PureSOx Training Centre gives Alfa Laval autonomy in providing on-the-job training to commissioning engineers. Trainees will no longer have to wait for a suitable vessel and installation, but will instead be able to hone their commissioning skills in an environment that is as close to reality as possible. This will ensure that they are fully prepared for the onboard work of bringing customer systems online.

In keeping with this thinking, the design of the open-loop system is based on an existing customer project. However, instead of being connected to an engine, the facility’s scrubber is part of a detailed simulation, in which no exhaust gas is used but values and signals related to the exhaust gas are accurately reproduced. Because the system has all of the real ancillaries, including valves and pumps, it does use a real flow of water, which is recirculated to minimize waste.

Erik Haveman, Sales Director, Exhaust Gas Cleaning.

Erik Haveman, Sales Director, Exhaust Gas Cleaning.

“We’ve shortened the scrubber a bit to fit it indoors, and there are plexiglass portholes and internal lighting that allow trainees to see the flow within the scrubber,” Haveman says. “But in all other respects, right down to the Alfa Laval Touch Control system, the look, feel and overall experience is exactly what it would be on board.”

A training resource for customers as well

Having the PureSOx Training Centre in Shanghai will increase the speed and effectiveness of training Alfa Laval commissioning engineers during the ramp-up phase connected to 2020. “This is an important step in delivering to customers, who depend on us to bring their systems into operation smoothly,” says Haveman.

As a further and ongoing service to customers, the new facility will also be possible to use for crew trainings. The unique setup, which pairs an accurate onboard experience with focus and calm that are seldom found on a real vessel, will be as beneficial for crew learning as it is for Alfa Laval’s own engineers.

“We invite all customers to Shanghai, whether for training or simply to see a PureSOx scrubber in person,” says Haveman. “When they visit, it will be our pleasure to show them how we train our own staff to meet their needs.”

To learn more about Alfa Laval PureSOx and Alfa Laval’s approach to exhaust gas cleaning, visit www.alfalaval.com/puresox

Editor’s notes

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, in oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena. Alfa Laval is listed on Nasdaq OMX, and, in 2018, posted annual sales of about SEK 40.7 billion (approx. 4.0 billion Euros). The company has about 17 200 employees.