MBPX

Alfa Laval MBPX is a high-performance pharmaceutical centrifuge range engineered for the demanding needs of the pharmaceutical industry. Separation of suspended particles typically sized 0.5 – 500µm is highly efficient thanks to the unique gentle processing. The range includes machines from small batches and advanced separation systems to large-scale vaccine and probiotics production.

Experience the benefits of the MBPX separator range, designed for vaccine production

- High product yield with minimal losses

- Engineered to meet stringent hygiene requirements

- High separation efficiency reduces fouling of downstream polishing filters

- Foam free and gentle process

MBPX separators are used in the production of vaccines and other biopharmaceutical products, typically for clarification processes, such as harvesting microbial cells, cell cultures, and precipitated proteins.

What makes MBPX unique?

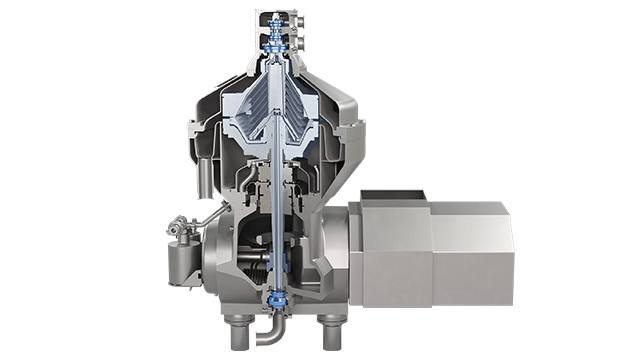

Hermetic Design™

Thanks to the unique Hermetic Design™, the MBPX separator achieves gentle, foam-free processing, resulting in high yield and minimal product losses. The fully hermetic conditions also enhance hygienic design by ensuring all contact surfaces are wetted during CIP (Cleaning-in-Place). Additionally, the airtight bowl improves fluid dynamics, reducing power consumption by up to 60% compared to non-hermetic alternatives.

UniDisc™

Alfa Laval UniDisc™ increases disc area for improved separation capacity by up to 30%, while at the same time providing an easy to clean design and never-before-seen degree of hygiene.

Customized pharmaceutical centrifuge systems

MBPX separators are available as fully automated, customized pharmaceutical centrifuge systems that prioritize both safety and processing efficiency. Smaller units come as skid-mounted solutions, while larger systems are offered as modular setups. These include piping and service liquid components, electrical control systems, and PLCs — all pre-assembled and factory-tested for optimal reliability.

Service

Підтримка вашого обладнання в оптимальном робочому стані

Наша Глобальна мережа сервісних центрів у будь-який час готова забезпечити постачання запасних частин та підтримку при експлуатації і технічному обслуговуванні вашого обладнання, де б не знаходилися ваші виробничі потужності. Збільшуючи час безвідмовної роботи обладнання, гарантуючи постійну експлуатаційну готовність і оптимізуючи режими роботи, ми допомагаємо вам знайти спокій і впевненість, а також підвищити окупність ваших капіталовкладень. Ми можемо, за спільною домовленістю з вами, включити наші послуги до складу Сервісної угоди, що дасть вам можливість заздалегідь знати обсяг, вартість і регламент обслуговування і забезпечить безперебійну роботу обладнання.

Test, validate, and scale up your next separation solution

Whether upgrading your production line or running a proof of concept, Alfa Laval helps you choose the right separator solution with confidence. Simply get in touch to arrange a consultation and trial at one of our test centres, or to rent a unit for onsite testing.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.